NICE K12 Cyber Education Conference – December 9-10, San Antonio, TX

If you are attending NICE K12, stop by our booth and see the robots and kits teachers use in cybersecurity and STEM education.

When you purchase your micro:bits from Parallax we reinvest the proceeds right back into our community programs.

We currently have seven of these kits in stock for our customers wishing to use them in their winter classes.

Whether you want one Scribbler S3 robot just for fun, or a 12-pack with accessories to outfit your classroom, now is the time to order! Shipped pre-programmed for play, the S3 is also programmable with online BlocklyProp and free tutorials.

Our educational curriculum is hosted on learn.parallax.com. You may browse by hardware type, programming language, or topic (robotics, electronics, projects).

If you are an instructor, you may also send us an e-mail to request access to the teacher’s guides, scope and sequence, assessment material, and standards and alignments.

If you are attending NICE K12, stop by our booth and see the robots and kits teachers use in cybersecurity and STEM education.

https://www.youtube.com/watch?v=On6CuQGuNvo YouTube’s “Baby Shark Video” was strange, hypnotic, and wildly popular five years ago. People loved it or felt otherwise quite strongly, but I thought

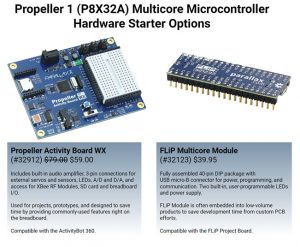

A customer recently wrote to me “there is so much focus on the Propeller 2, but the Propeller 1 (P1) does everything I need in

https://www.youtube.com/watch?v=J5AxYdFAZ1Q?feature=share In a prior news story we featured Daisy and her human, Kalie. Daisy showed us how dogs can add so much to the workplace,

This summer is shaping up to be the busiest one we’ve had in years with a half-dozen educational events across the country. While many are

“Mystery boxes are just a chance for Ken to sweep a bunch of obsolete junk off his desk into a box, and ask us to